Titanium plate / sheet

Competitive Factory Pricing: Source directly from our factory to get the best possible price, eliminating middlemen and maximizing your profit.

Fast & Flexible Supply: Benefit from our strategic stock and fast air freight options. We have no MOQ and welcome orders of any size.

Verifiable Quality: As an ISO 9001:2015 certified facility, we provide a full test report (MTC) with every order and support third-party verification.

Custom Solutions: We offer tailor-made solutions, including custom sizes and fabrication, to meet your precise project needs.

Free Samples Available: Contact us to request free samples for your testing and evaluation.

|

Grade |

GR1, GR2, GR3, GR4, GR5, GR7, GR9, GR11, GR12, GR23, etc. |

|

BT |

BT1-00, BT1-0, BT1-2, ОТ4-1, BT6, ПТ-7М, BT3-1, ПТ-3В, BT6Cetc |

|

Size |

0.5-100mm |

|

Standard |

ASTM B265, ASTM F136, AMS 4900, AMS 4901, AMS 4902,AMS 4911, AMS 4919, AMS 4914 |

|

ГОСТ 22178-76, ГОСТ 30522-97 |

Our Capabilities: Precision Manufacturing for Cost-Effective Solutions

We deliver a comprehensive range of titanium plate and sheet, engineered for performance and optimized for value. Our advanced manufacturing processes and rigorous quality control ensure you receive materials that not only meet the strictest international standards but also enhance your project’s cost-effectiveness.

1. Material Grades & Standard Compliance

Material Grades: We offer a full spectrum of materials to meet any requirement.

- Commercially Pure (CP) Series (Gr1, Gr2, Gr3, Gr4): Ideal for applications demanding excellent corrosion resistance and formability.

- Titanium Alloy Series (Gr5, Gr7, Gr9, Gr23, etc.): Provides superior strength, lightweight properties, and performance for advanced applications.

Manufacturing Standards: We manufacture in strict accordance with major international standards to guarantee quality and interoperability.

- Primary Standard: ASTM B265

- Biomedical Standard: ASTM F136

- Aerospace Specifications (AMS): Including AMS 4900, 4901, 4902, 4911, 4914, 4919.

- Other Standards: We can also supply materials compliant with JIS, DIN, GOST, and ISO upon request.

2. Customization & Fabrication Services

- Size Range: Our capabilities cover thicknesses from 0.5mm (0.02″) to 100mm (4″). We provide custom width and length cuts to optimize your material usage and reduce waste, saving you money.

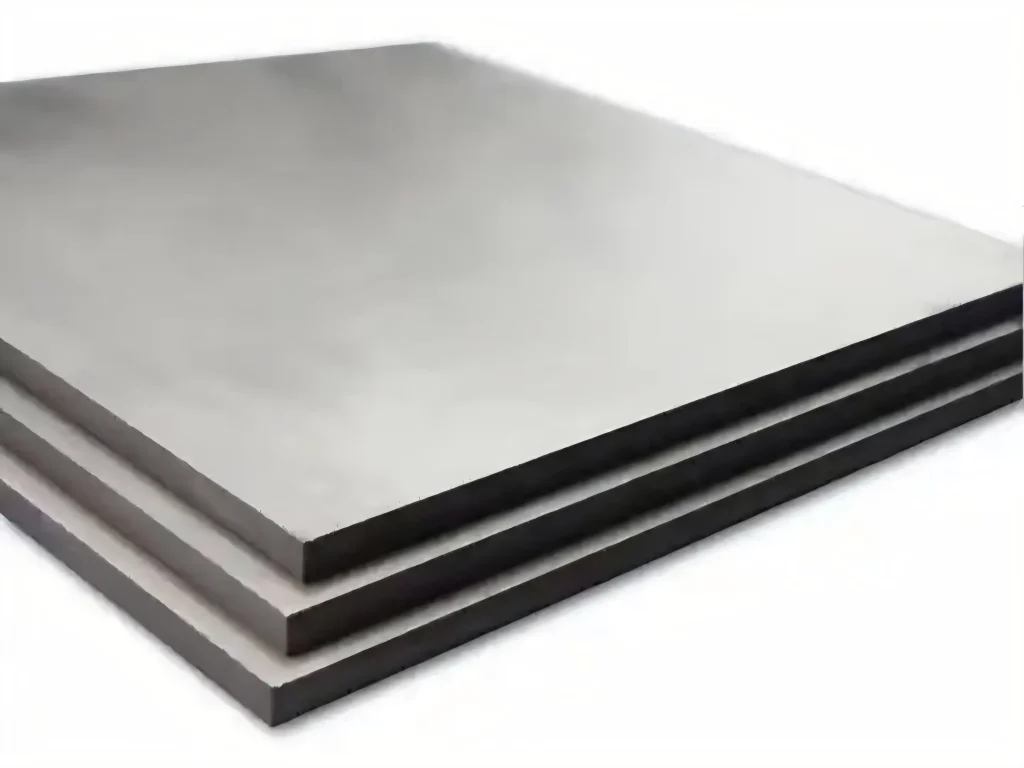

- Surface Finishes: Available in pickled, bright annealed, polished, and other finishes to meet your specific application needs.

- Precision Cutting & Fabrication: We offer advanced cutting (laser, waterjet, plasma) and fabrication services to deliver ready-to-use parts, streamlining your supply chain and reducing your internal processing costs.

3. Advanced Manufacturing & Quality Control

Manufacturing Processes:

- Our advanced hot and cold rolling processes produce materials with superior surface finishes and tighter tolerances, which minimizes your downstream machining time.

- Precise heat treatment (annealing, solution treatment, aging) is employed to optimize the material’s microstructure, ensuring reliable and consistent mechanical properties for your application.

Rigorous Quality Testing (Your Guarantee):

- We conduct a full suite of inspections to protect your investment. This includes Non-Destructive Testing (NDT) like Ultrasonic (UT) to ensure internal flawlessness, alongside comprehensive mechanical, chemical, and metallurgical tests.

- Full traceability is guaranteed. A complete material report is provided with every order, giving you complete peace of mind.