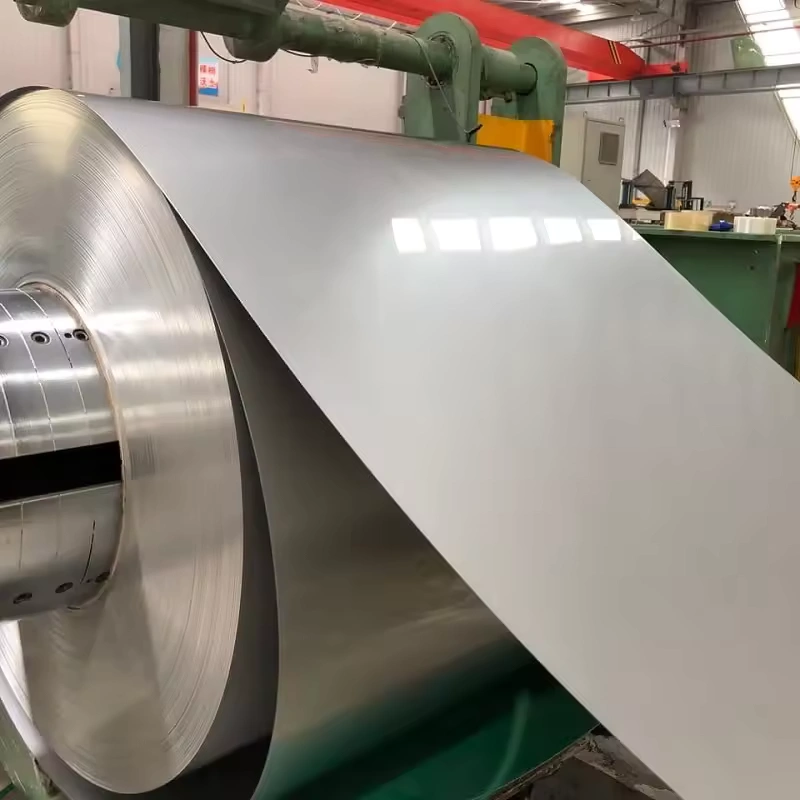

Titanium coil/strip

Competitive Factory Pricing: Source directly from our factory to get the best possible price, eliminating middlemen and maximizing your profit.

Fast & Flexible Supply: Benefit from our strategic stock and fast air freight options. We have no MOQ and welcome orders of any size.

Verifiable Quality: As an ISO 9001:2015 certified facility, we provide a full test report (MTC) with every order and support third-party verification.

Custom Solutions: We offer tailor-made solutions, including custom sizes and fabrication, to meet your precise project needs.

Free Samples Available: Contact us to request free samples for your testing and evaluation.

|

Grade |

GR1, GR2, GR3, GR4, GR5, GR7, GR9, GR11, GR12, GR23, etc. |

|

Size |

0.5-12mm |

|

Standard |

ASTM B265, ASME SB265, AMS 4911, ASTM F136, ASTM F67 |

High-Quality Titanium Coil & Strip: Factory-Direct Prices for Efficient Production.

As an ISO 9001:2015 certified factory, we specialize in manufacturing high-quality titanium coil and strip, designed to integrate seamlessly into your automated production lines. Our mission is to provide materials that enhance your manufacturing efficiency and reduce costs, backed by competitive factory-direct pricing and a commitment to fast, reliable delivery.

Our Advantage: The Smart Choice for Your Production Line

- Factory-Direct Pricing for Bulk Supply:By sourcing coils and strips directly from us, you gain a significant cost advantage. We eliminate distributor markups, making your large-scale production more profitable.

- Optimized for Automated Manufacturing:We provide coils with standard inner diameters and custom weights, perfect for continuous feeding into automated stamping or forming lines. Our high-precision slitting and edge processing deliver materials ready for immediate use, reducing your setup time.

- Verifiable Quality for Consistent Performance:We conduct rigorous inspections, including chemical analysis, online thickness/width measurement, and mechanical property testing. A complete material report (MTC) is provided with every coil to guarantee full traceability and batch-to-batch consistency.

- Flexible & Fast Supply:We support your projects with a no Minimum Order Quantity (MOQ) policy and maintain a strategic stock for urgent needs. With our fast air freight options, your materials arrive on schedule, preventing production downtime.

Technical Specifications

Material Grades:

- Commercially Pure (CP) Series (Gr1, Gr2, Gr3, Gr4): Ideal for chemical linings, battery electrodes, and precision stamped parts requiring high ductility and corrosion resistance.

- Titanium Alloy Series (Gr5, Gr7, Gr9, Gr23, etc.): Provides high strength for aerospace structures and biocompatibility for medical components.

Compliance Standards:

- General: ASTM B265 / ASME SB265.

- Aerospace: AMS 4911.

- Biomedical: ASTM F136, ASTM F67.

- We can also supply materials compliant with JIS, DIN, GOST, and ISO upon request.

Size & Customization:

- Thickness: Available in a range from 0.5mm (0.0196″) to 12mm (0.47″).

- Width & Edge: Custom narrow strip slitting and various edge conditions (Mill, Slit, Deburred) are supported.

- Coil Specifications: Custom lengths, coil IDs/ODs, and weights are available to match your equipment requirements.

- Surface Finishes: Available in pickled, bright annealed, cold-rolled polished, and other custom conditions.