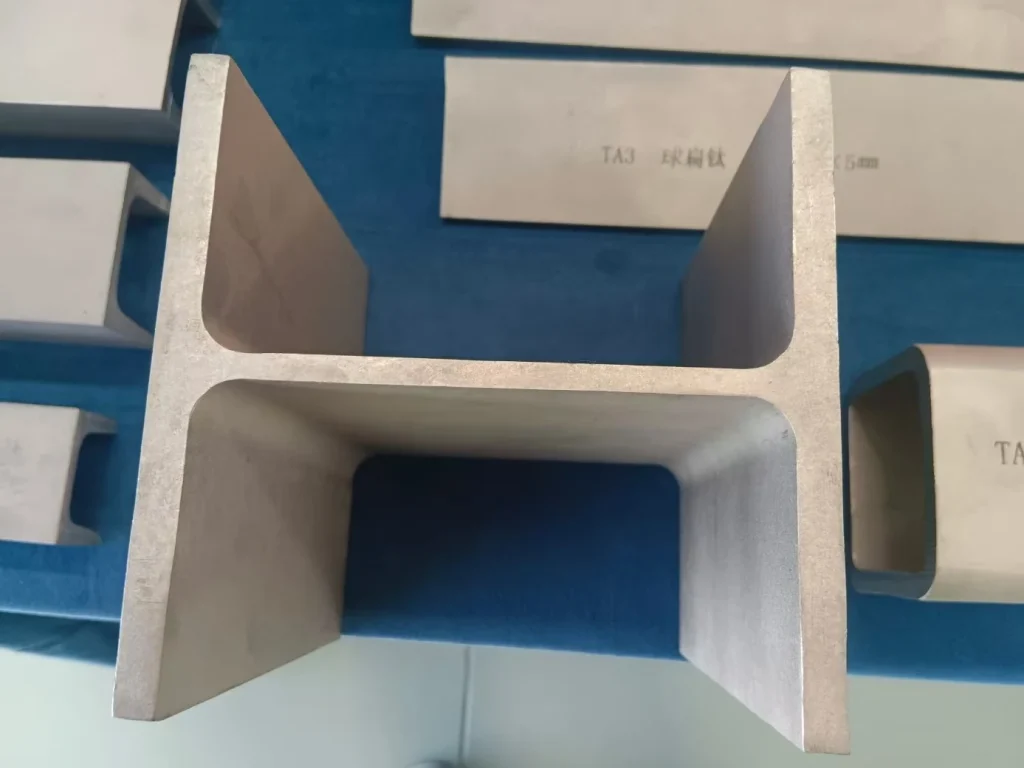

Titanium U-shaped groove

Competitive Factory Pricing: Source directly from our factory to get the best possible price, eliminating middlemen and maximizing your profit.

Fast & Flexible Supply: Benefit from our strategic stock and fast air freight options. We have no MOQ and welcome orders of any size.

Verifiable Quality: As an ISO 9001:2015 certified facility, we provide a full test report (MTC) with every order and support third-party verification.

Custom Solutions: We offer tailor-made solutions, including custom sizes and fabrication, to meet your precise project needs.

Free Samples Available: Contact us to request free samples for your testing and evaluation.

Custom Titanium U-Shaped Groove: Precision Fabrication at Factory-Direct Prices.

As an ISO 9001:2015 certified factory, we are your direct source for custom-fabricated titanium U-shaped grooves (U-channels). We specialize in transforming your designs into high-performance components that offer the perfect balance of strength, corrosion resistance, and lightweight properties, all delivered with the speed and value your projects demand.

Our Advantage: The Smart Choice for Custom Profiles

- Factory-Direct Pricing: By sourcing your custom U-channels directly from our manufacturing facility, you bypass distributor markups, significantly reducing your costs for both prototypes and large production runs.

- Precision Fabrication to Your Specs: We are experts in custom fabrication. Using advanced techniques like press braking, extrusion, and CNC machining, we manufacture U-shaped grooves to your exact drawings, ensuring tight tolerances and perfect conformity.

- Verifiable Quality: Our commitment to quality is absolute. All products are manufactured under our rigorous ISO 9001 system and ship with a full Mill Test Certificate (MTC). We support third-party verification to guarantee the material and dimensional accuracy of every part.

- Agile & Fast Supply: We support projects of all sizes with a no Minimum Order Quantity (MOQ) policy. Our efficient production planning and fast air freight options ensure your custom components are delivered on schedule.

Key Features & Applications

Our titanium U-shaped grooves deliver superior performance in demanding environments:

- Exceptional Strength & Wear Resistance: With a tensile strength of over 900MPa (for Gr5), they are ideal for high-load structural parts like guide rails, support beams, and mounting brackets in industrial machinery and aerospace.

- Superior Corrosion Resistance: Naturally immune to saltwater, acids, and alkalis, making them the first choice for structural supports in marine environments, chemical processing plants, and offshore platforms.

- Lightweight Performance: Being 40% lighter than steel, they are critical for reducing weight in aerospace frames, high-performance vehicles, and specialized robotics without sacrificing strength.

- Extreme Temperature Stability: Maintain excellent mechanical properties in both cryogenic and high-temperature environments, suitable for military and aerospace applications.

Technical Specifications

Manufacturing Methods:

- Press Braking / Bending: For forming U-channels from titanium plate/sheet. Ideal for a wide range of sizes and thicknesses.

- Hot Extrusion: For producing complex or seamless U-profiles with excellent grain structure, suitable for high-stress applications.

Material Grades:

- High Strength: Ti-6Al-4V (Grade 5), Ti-6Al-4V ELI (Grade 23)

- High Formability & Corrosion Resistance: Commercially Pure (CP) Titanium (Grade 1-4)

- Other Alloys: Ti-3Al-2.5V (Grade 9), Ti-5Al-2.5Sn (Grade 6), and others available upon request.

Dimensions & Tolerances:

- Height, width, thickness, and length are fully customizable according to your technical drawings. We can achieve precise dimensional and geometric tolerances to meet your assembly needs.

Surface Finishes:

- Available in pickled (satin), sandblasted, or polished finishes.