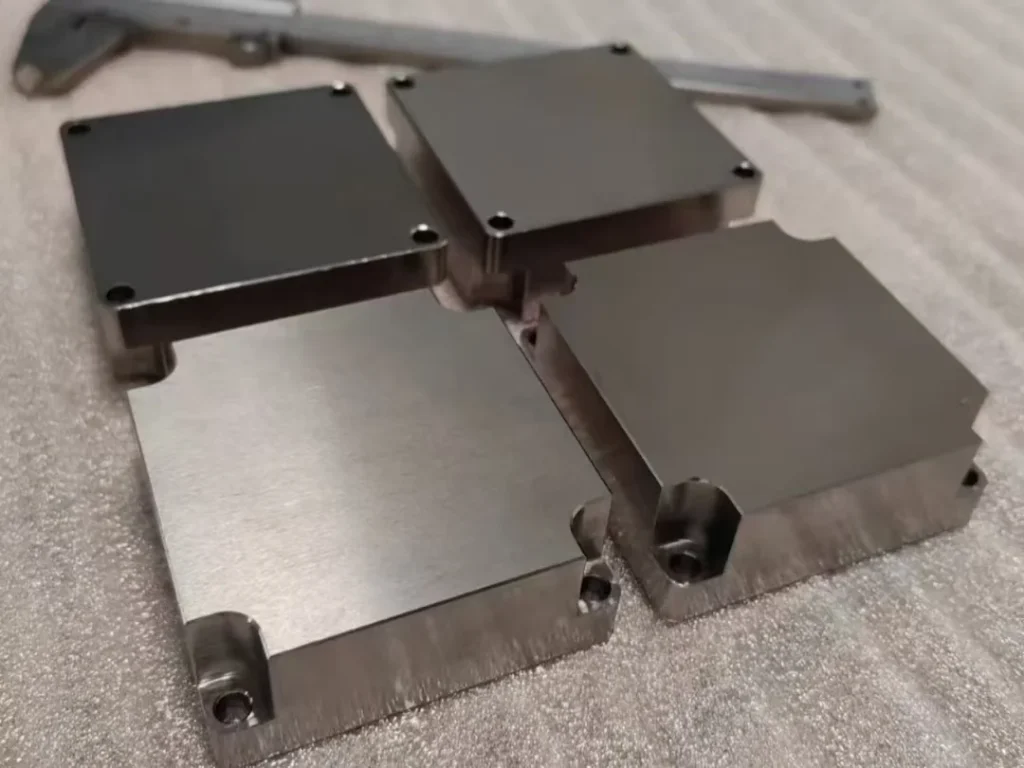

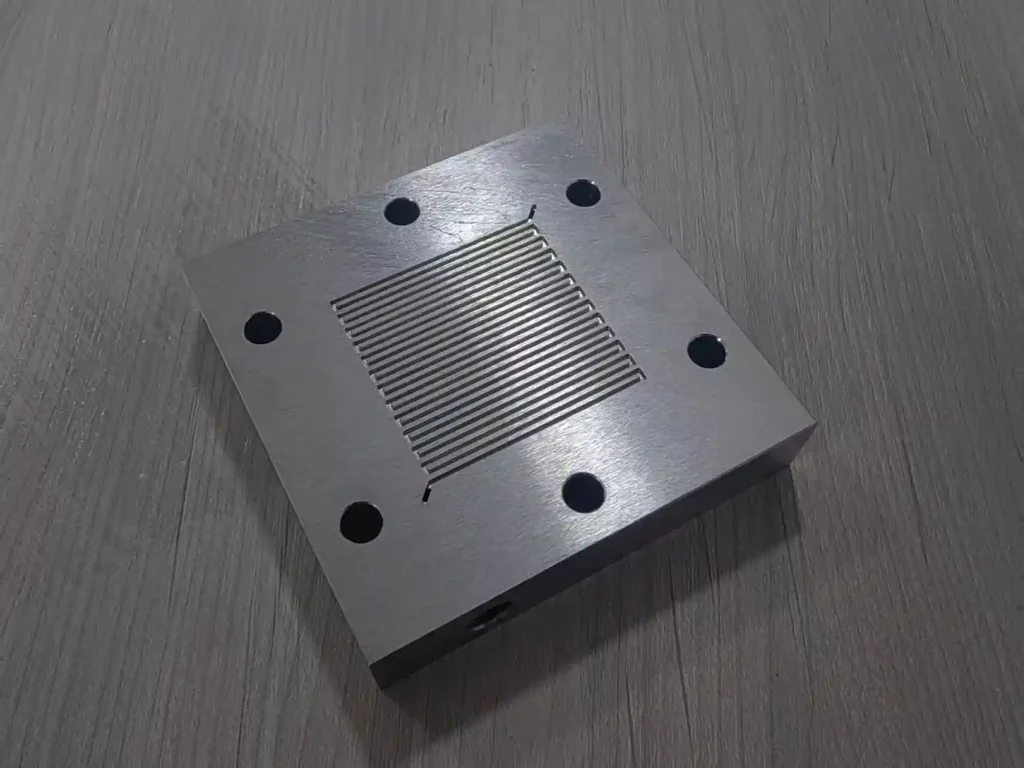

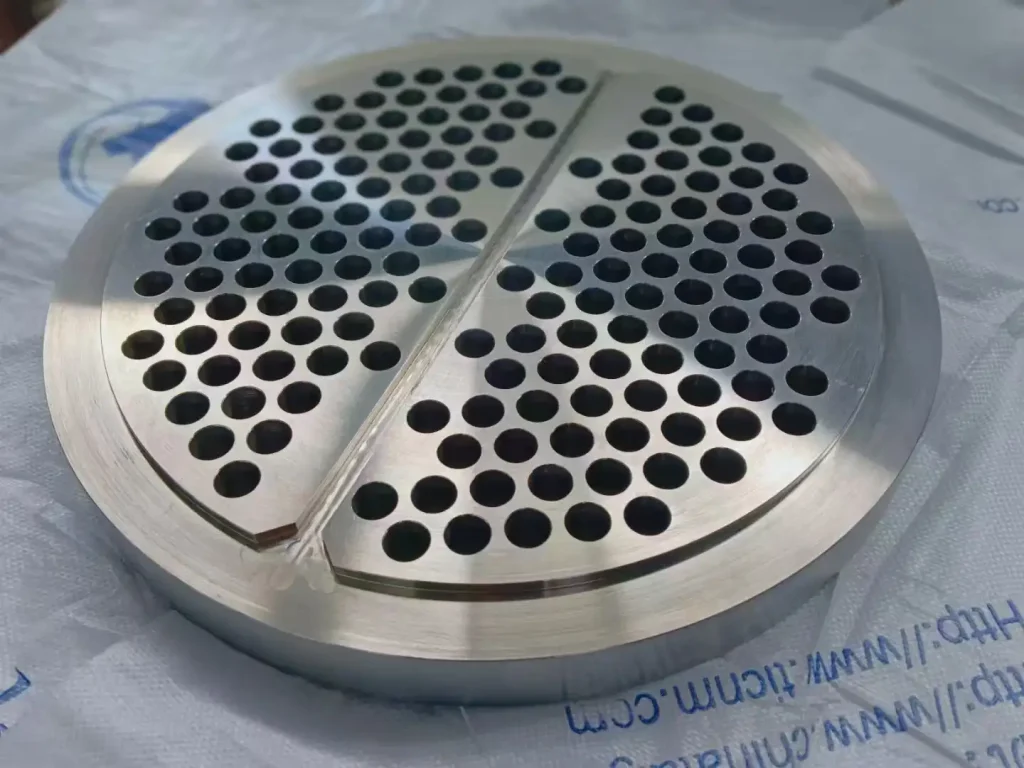

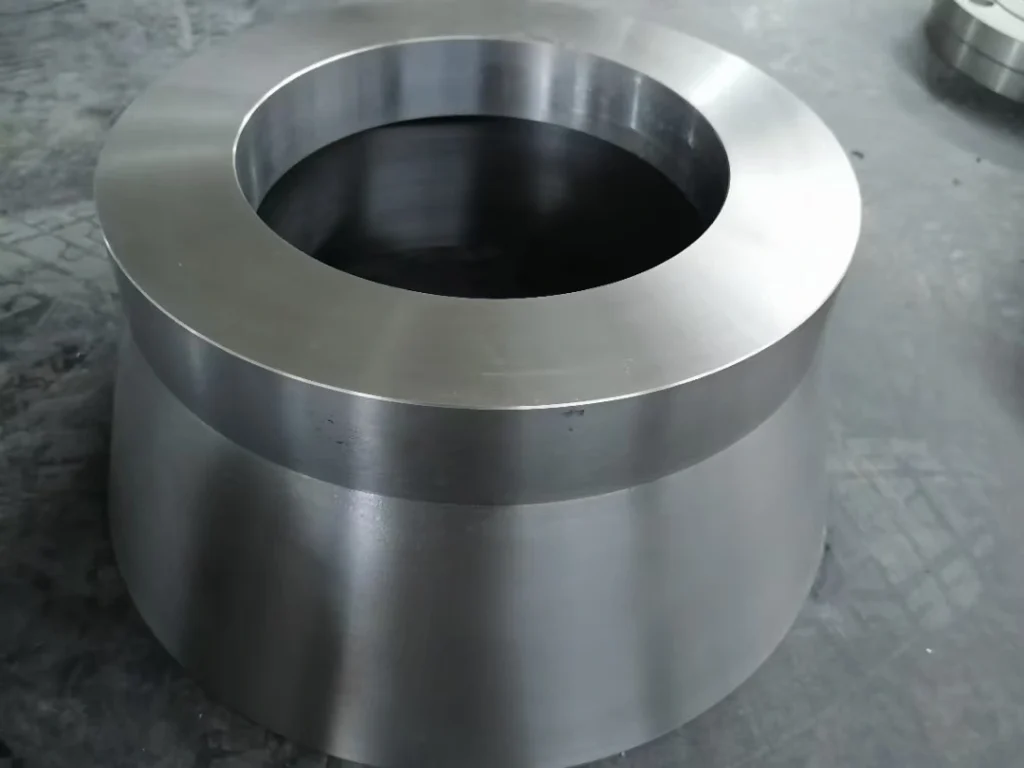

Titanium Custom Part

Quality:Provide test report or independent third party certification.

Customised: tailor-made exclusive solutions for you and any need, whether personal or corporate.

Test samples: Free samples are available for testing.

Minimum order quantity: None, we respect every need of our users, as long as you need to.

Business: ISO 9001:2015 Specialized Titanium Production Plant

Custom Titanium Parts: From Drawing to Delivery, Fast & Affordable.

As an ISO 9001:2015 certified factory, we are your direct manufacturing partner for high-quality custom titanium parts. We specialize in transforming your technical drawings into precision-finished components with a streamlined process designed to save you time and money.

Our Advantage: The Smart Choice for Custom Manufacturing

- Factory-Direct Pricing:By sourcing your custom parts directly from our manufacturing facility, you get the most competitive price. We provide transparent quotes that eliminate distributor markups, making high-performance custom parts more affordable.

- Verifiable Quality & Precision:Our commitment to value is backed by rigorous quality control. We use advanced inspection equipment like CMMs and conduct NDT (UT, RT, PT) to ensure every part meets your exact specifications. Every order ships with a full Mill Test Certificate (MTC) and supports third-party verification.

- One-Stop Manufacturing Solution:Simplify your supply chain. We handle the entire process in-house, from raw material selection to multi-axis CNC machining, forging, welding, and surface finishing. We deliver ready-to-use parts, saving you the effort of managing multiple suppliers.

- Agile & Fast Supply:We support projects of all sizes with a no Minimum Order Quantity (MOQ) policy, perfect for rapid prototyping. Our efficient production planning and fast air freight options ensure your custom parts are delivered on schedule.

Our Comprehensive Capabilities

Processable Materials:

- Commercially Pure (CP) Titanium Series: Gr1, Gr2, Gr3, Gr4.

- Titanium Alloy Series: Gr5 (Ti-6Al-4V), Gr23 (Ti-6Al-4V ELI), Gr7, Gr9, and more.

Primary Manufacturing Processes:

- Precision CNC Machining (Multi-axis Turning, Milling, Drilling)

- Forging (Open-die, Closed-die)

- Laser, Waterjet & Plasma Cutting

- Precision TIG Welding & Assembly

- Bending & Forming

- Surface Treatments (Anodizing, Polishing, Sandblasting)

Precision & Standards:

- We are capable of achieving strict, micron-level (µm) tolerances and adhere to international standards like ASTM, AMS, and ISO 9001:2015.