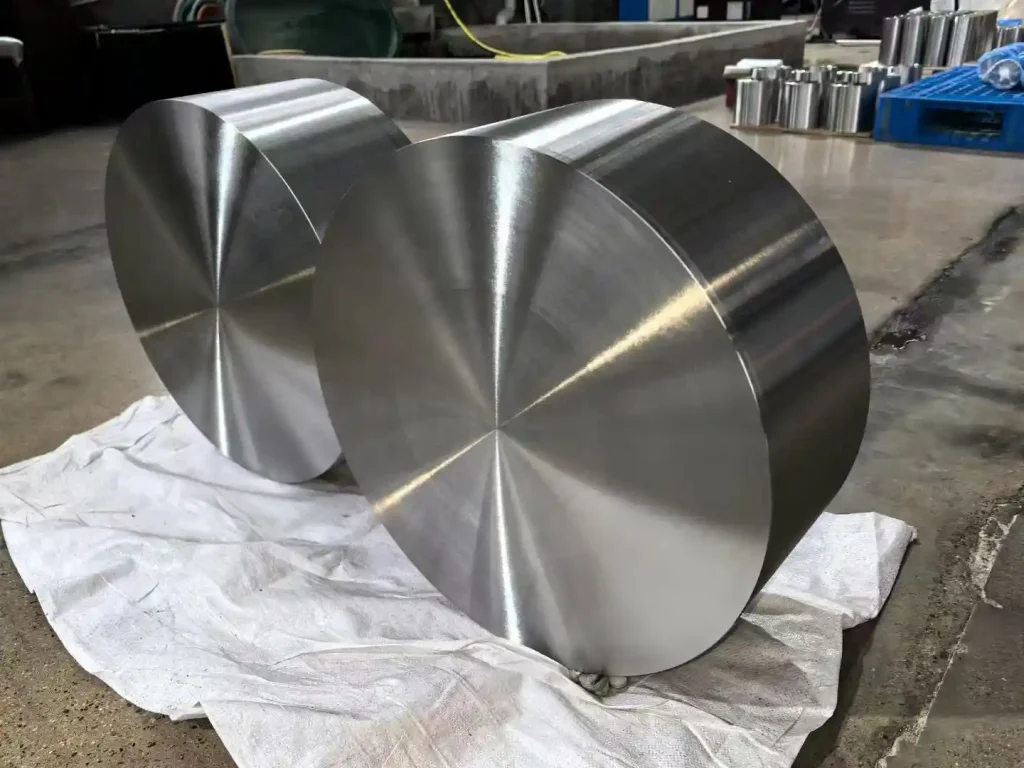

Titanium forging

Competitive Factory Pricing: Source directly from our factory to get the best possible price, eliminating middlemen and maximizing your profit.

Fast & Flexible Supply: Benefit from our strategic stock and fast air freight options. We have no MOQ and welcome orders of any size.

Verifiable Quality: As an ISO 9001:2015 certified facility, we provide a full test report (MTC) with every order and support third-party verification.

Custom Solutions: We offer tailor-made solutions, including custom sizes and fabrication, to meet your precise project needs.

Free Samples Available: Contact us to request free samples for your testing and evaluation.

|

Grade |

GR1, GR2, GR3, GR4, GR5, GR7, GR9, GR11, GR12, GR23, etc. |

|

BT |

BT1-00, BT1-0, BT1-2, BT6, BT3-1, ПТ-3В, BT6C, BT25, ВТ25У, etc. |

|

Size(Forging block) |

L:40-6000mm W:40-2000mm H:20-1200mm or customizable |

|

Size(Forging round) |

φ40-φ3000mm Thickness:20-1000mm or customizable |

|

Standard |

ASTM F136,ASTM B348, ASTM B381, AMS 4928 |

|

GOST 26492-85, GOST 22177-76, OST 1 90173-75 |

Precision Titanium Forgings: Superior Strength at Factory-Direct Prices.

As an ISO 9001:2015 certified factory, we are your direct source for high-performance titanium forgings. We specialize in providing custom-forged components that offer the ultimate blend of strength, toughness, and reliability, all delivered with the speed and value your projects demand.

Our Advantage: The Smart Choice for High-Performance Components

- Factory-Direct Pricing:By sourcing your custom forgings directly from our manufacturing facility, you bypass distributor markups. This ensures you get the most competitive price for high-strength parts, from raw forged blocks to fully machined components.

- Advanced Forging & Machining Capabilities:We are a one-stop solution for your forging needs. Our facility is equipped with large hydraulic presses and die forging hammers, utilizing advanced open-die, closed-die, and ring rolling techniques. With in-house high-precision CNC machining, we can deliver parts that are ready for assembly, saving you time and costs.

- Verifiable Quality & Full Compliance:Our competitive pricing is backed by an uncompromising commitment to quality. We conduct rigorous inspections, including UT for internal flaws and PT for surface defects. Every forging ships with a full Mill Test Certificate (MTC) and we support third-party verification to guarantee full compliance with standards like ASTM and AMS.

- Agile & Fast Supply for Custom Projects:We support projects of all sizes with a no Minimum Order Quantity (MOQ) policy. Our efficient production planning and fast air freight options ensure your custom forgings are delivered on schedule.

Technical Specifications

Available Forging Forms:

- Forging Blocks: Up to 6000mm in length.

- Forging Rounds & Discs: Up to φ3000mm in diameter.

- Forging Rings, Bars & Shafts.

- Custom Shaped Forgings: Manufactured to your exact drawings.

Material Grades:

- Commercially Pure (CP) Series (Gr1, Gr2): For applications demanding excellent corrosion resistance and good ductility.

- Titanium Alloy Series (Gr5, Gr7, Gr9, Gr23, etc.): For components requiring high strength, and fatigue and corrosion resistance.

Compliance Standards:

- Forging Standards: ASTM B381 / ASME SB381.

- Aerospace Standards: AMS 4928 (for Ti-6Al-4V).

- Biomedical Standards: ASTM F136 (for Gr23), ASTM F67 (for CP Grades).

- We also supply materials compliant with JIS, DIN, GOST, and ISO upon request.

Finishing & Tolerances:

- Surface Finishes: Available in black forged, rough machined, or fully finish machined conditions.

- Tolerances: We conform to all relevant forging standards and can provide tighter, precision-machined tolerances as required