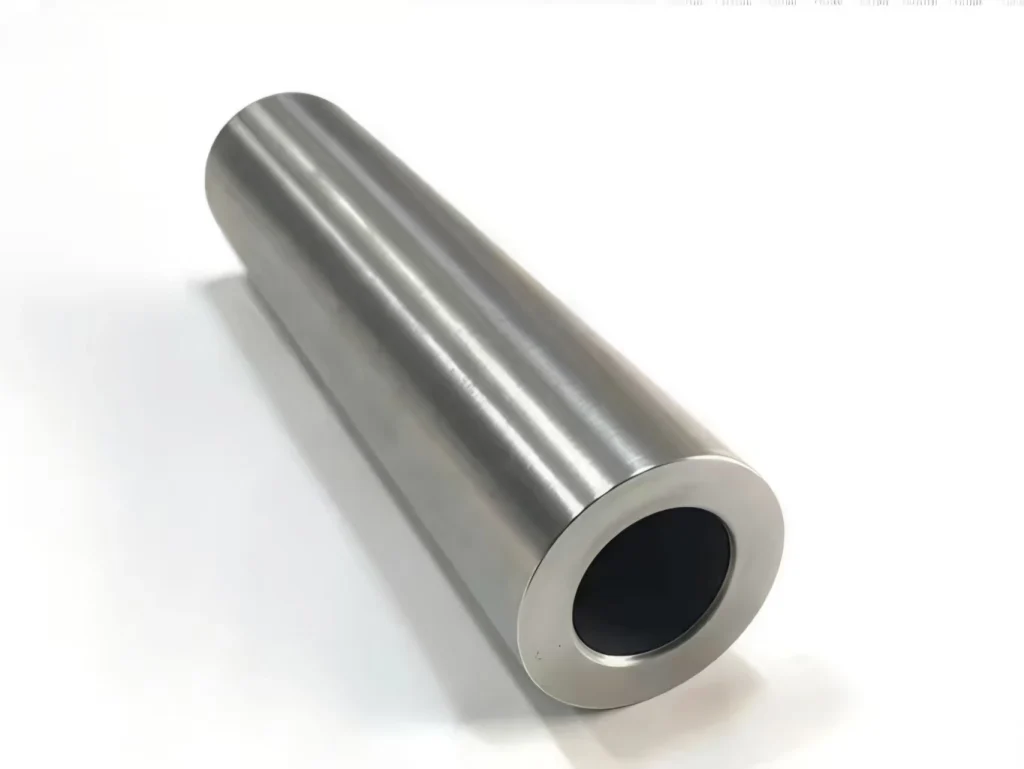

Titanium pipe / tube

Competitive Factory Pricing: Source directly from our factory to get the best possible price, eliminating middlemen and maximizing your profit.

Fast & Flexible Supply: Benefit from our strategic stock and fast air freight options. We have no MOQ and welcome orders of any size.

Verifiable Quality: As an ISO 9001:2015 certified facility, we provide a full test report (MTC) with every order and support third-party verification.

Custom Solutions: We offer tailor-made solutions, including custom sizes and fabrication, to meet your precise project needs.

Free Samples Available: Contact us to request free samples for your testing and evaluation.

|

Grade |

GR1, GR2, GR3, GR4, GR5, GR7, GR9, GR11, GR12, GR23, etc. |

|

BT |

BT1-00, BT1-0, BT1-2, BT6, BT3-1, ПТ-3В, BT6C, BT25, ВТ25У, etc. |

|

Welded Pipe Sizes: |

OD(90-1020mm)WT(0.5-50.0mm)L(as required) |

|

Seamless Pipe Sizes: |

OD (3 – 520 mm)WT(0.4 – 30 mm)L(as required) |

|

Standard |

ASTM B337, ASTM B338, ASTM B861, ASTM B862, GB/T 2924-2007, GB/T3625-2007 |

|

GOST 22897-86, GOST 24890-81, GOST 21945-76 | |

|

Test requirement |

Eddy Current Test, Hydrostatic Test, UT, Penetrant Test, Air underwater pressure Test, PMI Test,Spectro Test, Intergranular Corrosion Test, Sharpy Impact Test, Hardness Test, Tension Test(Elongation, Yield Strength, Tensile Strength), Flarring Test etc. |

|

Ends |

PE/Plain Ends, BE/Beveled Ends |

High-Quality Titanium Pipes & Tubes: Factory-Direct Prices, Fast Global Delivery.

As an ISO 9001:2015 certified factory, we are your direct source for a comprehensive range of high-performance titanium pipes and tubes. Our mission is to streamline your supply chain by delivering verifiable quality at competitive factory-direct prices, supported by flexible service and a commitment to rapid global delivery.

Our Advantage: The Smart Choice for Your Supply Chain

- Factory-Direct Pricing & Value:Source directly from our manufacturing facility to bypass distributor markups. We offer the best possible value on both seamless and welded tubes, helping you reduce project costs and increase profitability.

- Verifiable Quality & Full Traceability:Our competitive pricing is backed by an uncompromising commitment to quality. We conduct rigorous inspections, including NDT (UT, Eddy Current) and pressure testing (Hydrostatic). Every order ships with a full Mill Test Certificate (MTC) to guarantee full traceability and compliance with international standards.

- Agile Supply with No MOQ:We support projects of all sizes with a no Minimum Order Quantity (MOQ) policy. With a strategic stock of common specifications and fast air freight options, we ensure your materials arrive on schedule, preventing production delays.

- Comprehensive Range & Expert Guidance:We offer a full spectrum of grades and sizes in both seamless and welded forms. Our expert team is ready to provide professional guidance to help you select the most cost-effective solution for your specific application.

Technical Specifications

Product Types & Size Range:

- Seamless Pipes/Tubes: Ideal for high-pressure, critical applications.

- OD: 3mm – 520mm

- WT: 0.4mm – 30mm

- Length: Up to 18 meters

- Welded Pipes/Tubes: A cost-effective choice for larger diameter needs.

- OD: 90mm – 1020mm

- WT: 0.5mm – 50mm

- Length: Up to 15 meters

Material Grades:

- Commercially Pure (CP) Series (Gr1, Gr2, Gr3, Gr4): Perfect for applications demanding excellent corrosion resistance, such as in chemical processing and desalination.

- Titanium Alloy Series (Gr5, Gr7, Gr9, Gr23, etc.): Provides superior strength and performance for aerospace, medical, and high-performance applications.

Compliance Standards:

- We manufacture in strict accordance with major international standards, including ASTM B337, B338, B861, B862, as well as ASME, DIN, and JIS upon request.

Customization:

- Custom lengths, polished or sandblasted surface finishes, and beveled ends (BE) are available to meet your project’s specific requirements.